This is a huge slab of ash. It's an old tabletop that I salvaged from the side of the road on trash day a year or so back. It's been sitting in my garage ever since waiting for the right project. It's almost 7ft tall, by 38" wide (213cm x 96cm)

Recently, we rearranged our home office, and because of that we had a need to move a printer. We either had to fit two printers in the space of one, or move a printer to another part of the house. I went with the first option, and this giant tabletop was going to provide the raw materials.

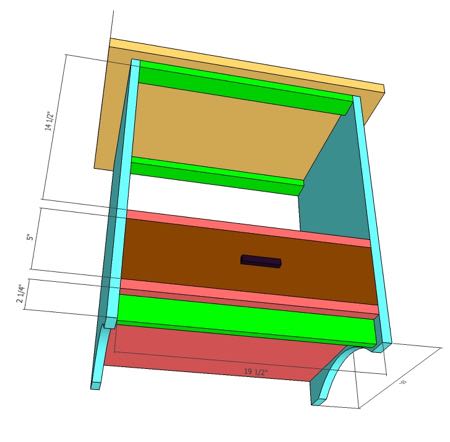

I spent some time in sketchup and came up with a simple plan, shown here. These were also sized to ensure that all the parts (except for the drawer carcass) would come out of this table top.

I cut up the table top into a bunch of pieces. While doing so, I concluded that this printer stand was going to be WAY TOO HEAVY. This table top was almost 1-1/8" thick (2.8cm). I needed to plane the parts down to something closer to 3/4" thick (1.9cm). This would also take care of getting rid of the old finish.

So I had to cut the pieces up more, in order to have them fit through the planer, plane them down a lot, and then laminate them back together. (Not shown). I did keep the top thicker than the rest; I left it 1 inch thick (2.5cm) since I think a thicker top looks nice.

Since this is just a piece of utilitarian office furniture, I elected to use pocket hole joinery. They're quick, simple, and completely strong enough. That said, I still positioned them to be hidden from view. Here you can see the bottom shelf, and the pocket holes are positioned to be on the bottom side of the shelf, and therefore hidden.

I also assembled the drawers with pocket hole screws. I used 3/4" stock, since I had some laying around. This works well with pocket hole joinery. You can use 1/2" stock, but then you need to use skinnier screws, so they don't poke out of the holes.

When using pocket hole joinery with drawers, the screws are in the front and back panels. The front panel is covered by a face, and the back faces the inside, so again, the pocket holes are never seen.

Here is the finished drawer being test-fitted. I used wood-on-wood for this cabinet, rather than drawer slides.

I applied a clear coat on the cabinet top, and on the drawer body. The rest of the cabinet was stained ebony. This would colour it black, but still have the grain visible. I've built other furniture with this type of finish (dark base, natural top) and we think it looks fine. The cabinet base was attached to the top using screws in elongated holes to allow for wood movement. I elongated the holes a bit by just wiggling the drill bit back and forth while drilling.

Here below are some photos showing the finished piece.

Some of the Tools/Supplies Used In This Project: (Affiliate Links)

Irwin Quick Grip XP600 Clamps

Dowelmax Company

NOTE: at the time of publishing (May 2023) Dowelmax is not currently available on amazon. It has been in the past, so I am keeping the following links, but right now only the link above to "dowelmax.com" is known to work.

Dowelmax Dowel Joinery Kit

Dowelmax Drill Guides for 1/4" Dowels

Dowelmax Dowels

Kreg Pocket Hole Clamp

Kreg Pocket Hole Jig

(I have older versions of these Kreg tools)

Jorgensen Cabinet Master Parallel clamps

DeWalt DW735 Planer

3rd party blades for DW735

As an Amazon Associate I earn from qualifying purchases you make using my affiliate links.